VIBRO SYSTEM

without agitator for professional double disc fertilizer spreaders

What is VIBRO SYSTEM?

Vibro System is Eurospand’s unique vibrating bottom hopper system consisting of a swash plate applied between the hopper bottom and the dispensing and feeding system.

How does it work?

By operating the power take-off (P.T.O.), the hopper bottom is placed in constant vibration throughout the entire dispensing.

What material is the Vibro System made of?

It is completely made of stainless steel.

Why do we not use the agitator inside the hopper in professional double-disc spreaders?

Because the agitators, during machine operation, impact the fertilizer producing rubbing and abrasion of the granules.

The consequence of these two actions is the crushing and pulverization of the fertilizer, which changes its nutritional characteristics and immediately releases the product’s properties to the soil (instead of diluting it over a longer, more optimal time), producing instantaneous over-fertilization and possible groundwater pollution.

Does the fertilizer overheat with the oscillating motion that the Vibro System produces in motion?

No, it does not. The fertilizer does not overheat as the oscillating motion of the Vibro System does not produce heat during operation.

What are the advantages of “not overheating” the product by using the Vibro System?

If no heat is generated and the crushing and pulverization of the fertilizer is avoided, it prevents the formation of lumps that can clog the passages through which the fertilizer must reach the dosing and distribution system.

Can seed be distributed with the Vibro System?

Absolutely! Since there is no rotating mechanism inside the hopper, the problem of seed breakage or etching does not occur, thus preventing the seed from not germinating.

What is the purpose of the sieve grid applied solidly above the oscillating bottom?

- It retains all lumps of fertilizer that, by reaching the openings of the quantity adjustment system, could compromise the constant and regular feeding of the distribution system.

- It ensures through vibration the outflow of fertilizer to the vibrating bottom even in the presence of substantial amounts of agglomerated product.

- It decreases and keeps constant the pressure exerted by the fertilizer on the feeding system to allow the machine to deliver a constant and continuous dose of fertilizer with any volume of product inside the hopper.

What products can you distribute with a fertilizer spreader equipped with Vibro System?

You can spread all types of mineral fertilizers, urea but also lime powder, sulfates, or pelleted organic fertilizers (particularly soft and crushable compared to mineral fertilizers) and normally not spreadable with traditional systems.

Vibro System is also recommended for broadcast seeding of various seeds and moistened rice.

The absence of friction normally caused by rotating agitators immersed in the product does not produce etching to the seeds and therefore does not affect their germination.

What is the advantage of border fertilization with a fertilizer spreader with Vibro System?

Thanks to the Vibro System feeding system, it is possible to feed a single disc even for a long time (an indispensable condition for field border fertilization) without running into the usual problems of product grinding and formation of lumps, which are often responsible for total or partial blockage of fertilizer outflow at the outlets remained closed.

Here is why different types of sieve grids can be supplied on request:

Eurospand has made different types of grids having holes with different geometries, which optimize distribution even for farmers who have to distribute particularly problematic products, such as pelleted organic fertilizers or seeds.

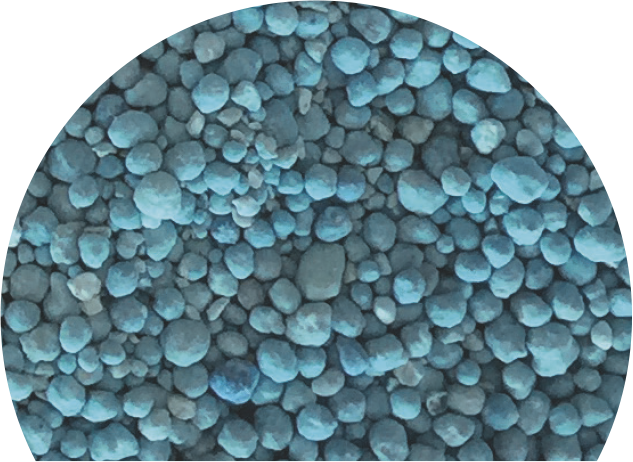

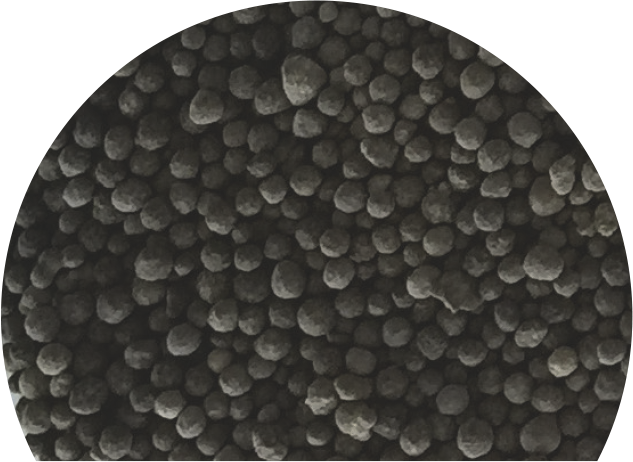

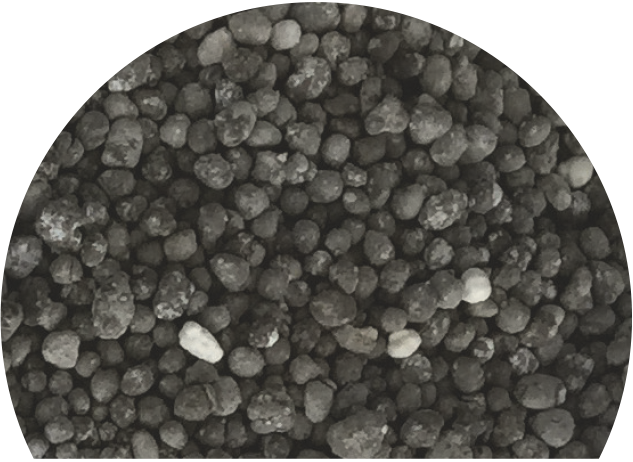

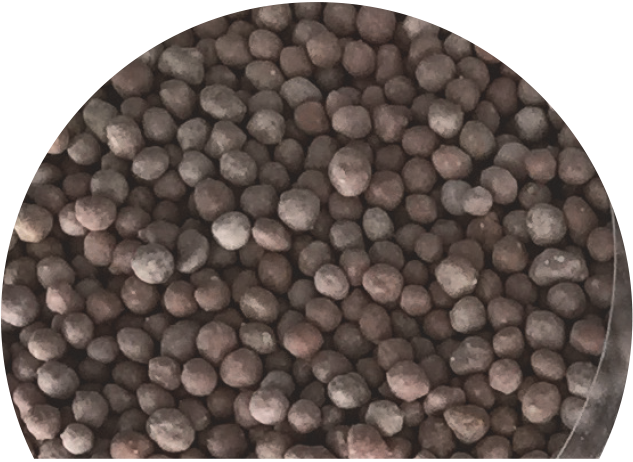

Some of the products that can be distributed